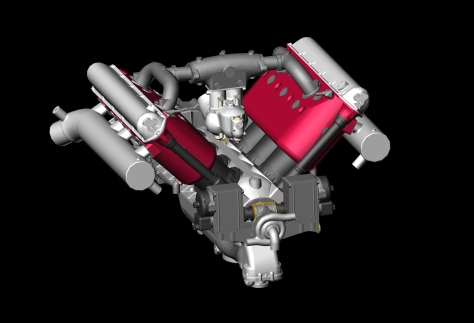

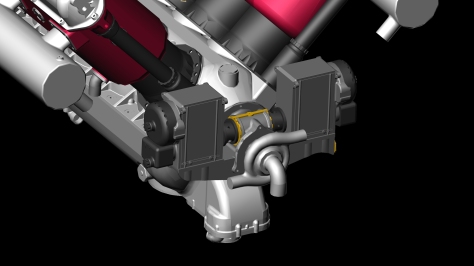

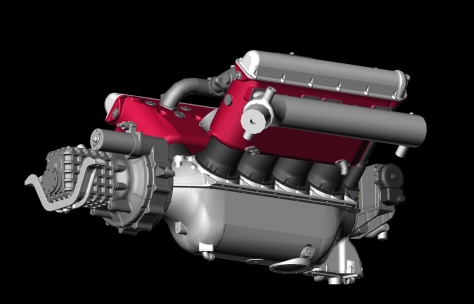

The CAD work on the licence built Hispano-Suiza 8F (Wright-Martin H3) is complete. The model has been made as per the aircraft version of the engine, but with some marine conversion parts added. The most notable and visible of those being the water cooled exhausts.

In addition to the exhausts I’ve also taken the liberty of moving the water pump from directly under the rear of the engine to the back. All of the marine conversions that I’ve seen have moved the water pump to somewhere else. I assume it’s to allow the engine to be mounted several inches lower in the boat, and so improve the C of G of the installation. I’ve also opted to keep the magneto driven ignition system at this point, though I may also draw up a more modern installation too eventually.

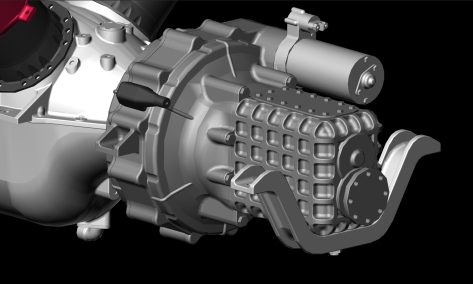

One area still to be resolved is the marine transfer gearbox. I intend to use the engine kit in future boat models and so have drawn up a notional modern style gearbox for those installations. I will also produce a period gearbox, but am waiting on some research information to do that.

With the CAD model virtually complete I’ve been in contact with a number of 3D Printing Bureaux to get prices and leadtimes, but in the current pandemic I assume they will be pretty heavily committed to work combating that.

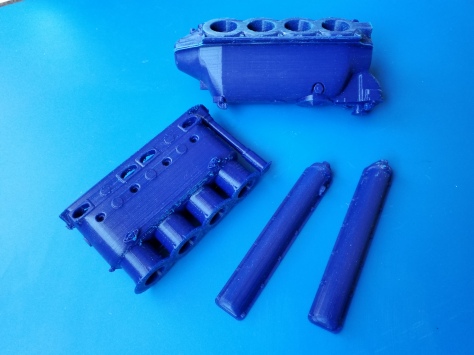

In the interim I have been printing the parts out on my own entry level machine. It can be a bit temperamental, is very slow and the quality of the output isn’t good enough for the finished model, but… It does allow me to check the parts and how they go together before I spend real money getting them done professionally. A number of mods have been incorporated into the model as a result of this already.

It will also provide me with a rough prototype of the model that I can use as a buck for making parts to, and so minimise handling of the proper model. I also intend to use it to design the mountings in the actual boat.

Hopefully this rather techie phase will be over soon and I can get back to real physical model making.

The design is really coming on. I wonder if modelling in the future will incorporate far more of this method?

LikeLike

It might inasmuch as people either provide print files free to download or sell them. There are already quite a few repositories on the net already.

The big barrier to doing what I have is learning to use CAD. The software is quite complex and, certainly in the initial stages, impenetrable. It still is at times when you know what you’re doing, just at a higher level!

Decent CAD programs are also prohibitively expensive.

LikeLiked by 1 person

I guess like many things, these costs may eventually fall, but I should think the technical aspect would certainly put a lot of people off. Thanks.

LikeLiked by 1 person

Don’t forget 99% of models (made) are kits and they are the same thing but just made by someone else.. this may mean that over time those manufacturers start to sell the stl files rather than the kit. Can see huge cost and environmental savings. The biggest handicap is the complexity and unreliability of resin printers. For this type of detail it has to be resin to print at c0.25um…

Are you detecting some frustration here? 🙂

Still trying.

LikeLiked by 1 person

You’re not selling me on resin printers here.😂

LikeLiked by 1 person

Huh ha… No, just my frustration in trying to print those models. I am going from one frustration to another. First sicking to the FEP film, which led to many holes and need for replacements. Then array check because no matter what rating it still stuck. Then replace LCD and glass, because that then failed due to pressure of gummy bears, and then last night the gearing failed as the printer is fighting the sticking between film and build plat as the gummy bear is sticking to both. And each time it takes an age and a lot of mess. Plus, I can’t remove the VAT this time as the bolt screws are too long and the build plate didn’t get high enough to slip it underneath. When it works, it’s great. When it doesn’t GGGGGGGGGGGGGGRRRRRRRRRRRRRRRRRRRR

LikeLiked by 1 person

I’ve been driven to distraction by my little Da Vinci Mini. Despite being billed as WiFi compatible, prints sent to it over my LAN always screw up, with some distinctly unhealthy chunterings being emitted by the printer. If I download via USB and calibrate before every print, they come out fine. It took an awful lot of wasted filament and frustration to get to this point though.

I’ve sent an arm and most of a leg off to a professional print bureau who have in turn promised to send me a set of Hispano engine parts. The cost was comparable to that of my printer!

When this model (Miss Severn) is done I may have to invest in an up-market resin printer. Formilabs are out of my reach, but something in the £1 – 1.5k might be on the cards.

LikeLiked by 1 person