Well it has been rather a long time since I was able to put an update on here, but hopefully they’ll be a bit more frequent in the future.

I’ve not been entirely dormant during the hiatus, but have done precious little physical modelling and rather a lot of CAD modelling. That has built up quite a backlog of CAD projects that need to be turned into physical models. They should appear in due course, health providing.

Miss Severn has languish on my lounge floor during the break from modelling and has been a frequent reminder of what I’ve been missing. However, I’m back now and Miss Severn has been receiving some much needed attention.

The hull has finally been given its first coat of varnish. Finding a crystal clear varnish that is compatible with the Tamiya acrylic rattle can paint has been a tale in itself. I’ve tested numerous products, most of which caused the paint on the test samples to pucker up and wrinkle. I did try using traditional yacht varnish, but the tint in that made the aquamarine hull colour go a peculiar shade of green. Water based resins were OK, but didn’t really give me the finish that solvent based ones can. No pictures of the hull unfortunately as I didn’t want to disturb it while the varnish is hardening. Dust is a perennial problem here.

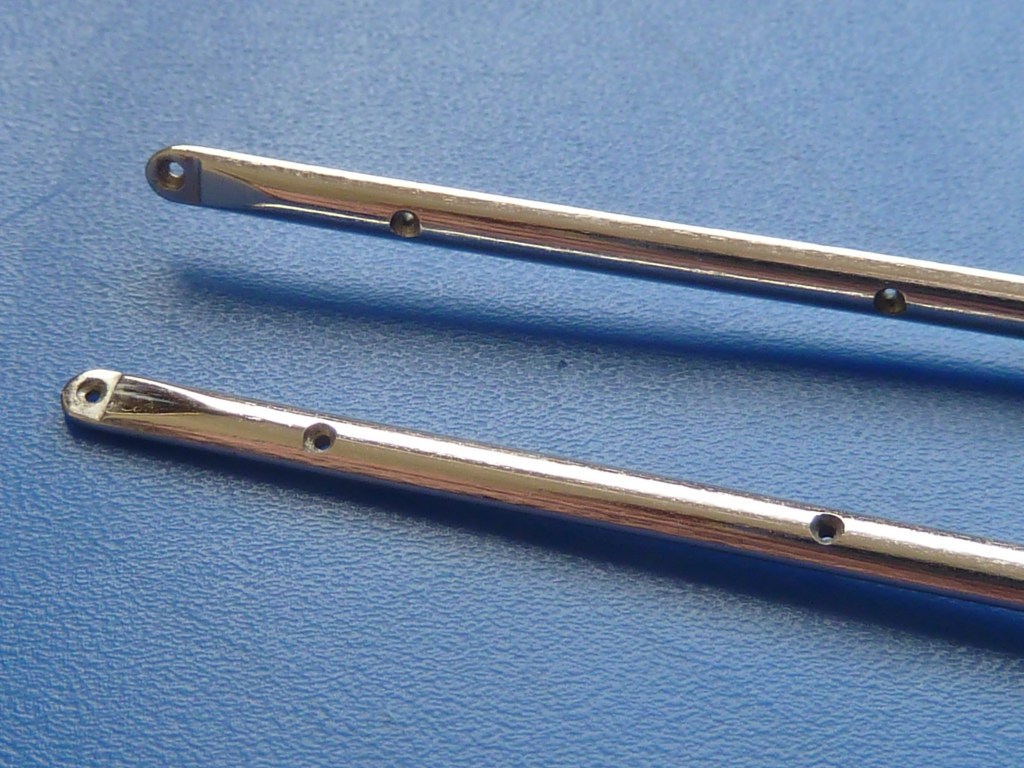

The other small bit of progress has been in bright nickel plating the rub rails for Miss Severn, and the Chris Craft 19′ Runabout. Miss Severn’s longest rails are about 40″ long which was much too large for my small facilities here. I did investigate sending them off to get them done professionally, but the quotes for that were also much too large.

In the end I opted to make a special plating tank out of 6mm PVC foam board and bought the necessary pure nickel anodes and titanium wire to connect them to the power supply. The whole affair looks a little Heath Robinson but does work surprisingly well. I was concerned about having a fairly unwieldy chemical bath knocking about in my garage but clamping it to the workbench makes it much more stable and an end tap allows 95% of the chemicals to drained off in situ. The bath only needs to be unclamped to recover the last few dregs.

The rails were polished up, cleaned with acetone, then given a copper strike coating. This isn’t strictly necessary with brass, but I wanted to make sure the bright nickel had a good base to adhere to. After the copper strike, the parts were given a quick rinse and then plated with bright nickel.

I’m happy with the result and it’s saved quite a few pennies.

Glad to hear from you again !

Cheers !

LikeLiked by 1 person

welcome back–we’re thrilled to read your new post! So interesting to see your solutions to things, like the long plating tank. Looking forward to more in the future!

LikeLiked by 1 person

Yet again, you come up trumps. Looking forward to seeing that hull.

LikeLiked by 1 person

I hope it turns out as good as you’re anticipating. Varnishing is my bete-noire. There is just so much dust around in this house. Trying to achieve a flawless finish is very difficult indeed.

LikeLike

It shall. PS, I am sure I’ve mentioned in one of our chats the appalling environment I do my work in. You would die. And no I will not show you any photos of the 1″ layer of dust!!!! 😀

LikeLiked by 1 person

Hello, Sorry I do not have your name. Hopefully this e-mail finds you in good health. I thought you might be interested in this project I am building for a Seal Major 4 cylinder 30cc engine I completed a while ago. Hopefully you recognize it. The scale is 1/6th of full size. I have followed your Miss Severn build with great interest and found it very informative. I wondered if I can get a little advice on the wood planking. I of course have lots of sanding and fairing to do before I’m at that stage. The model you built uses balsa for planking and I’m thinking that may be very soft on the interior even when coated with epoxy. It does however have the upside of making it easier to fair and get a nice finished form before the Mahogany strips are applied. Did you have any issues with the Cyanoacrylate glue seams being substantially harder than the balsa causing an uneven surface during sanding? The other wood I have been looking into is Limewood and I would love to know your thoughts on maybe using this as a replacement for the balsa. Can you remember what the thickness was on your balsa strips? Any help you can send my way during this build would be very much appreciated. Please let me know if you would like to follow this build and I will keep you updated on its progress. Thank you Mike Bontoft

LikeLike

The balsa was about 3.2mm thick (1/8″) if I remember correctly. I’ve not had any problems with the glue joints standing proud during sanding. I do always sand with a block though.

The internal coating of epoxy also makes it surprisingly tough. However, as far as the epoxy coating goes there seem to be 2 schools of thought on applying it. Some swear by thinning it with ethanol or IPA so that it penetrates further into the balsa. On the other hand, I’ve read comments from the epoxy producers saying this is uneccessary and actually weakens the application overall. I didn’t thin mine.

If you have doubts, build a few test sections to see how they fair. That wouldn’t take long.

I’m also always interested in following others’ builds.

Pete

LikeLike

Thanks for the quick reply Pete. Wife’s Birthday so got busy making some things for her. On the epoxy thinning I’ve had good luck with Acetone or MEK (stinky) and usually not diluted more than 10%. ð1/8 inch was what I was thinking of using for the planking, it is a considerably larger model but should be good. I’ve got some 1/8 balsa on the shelf so might have a play coating it with Epoxy. In the engine area where fuel and oil are present I could lay down some thin glass fabric maybe. I will send over some progress photos and if its OK may have some questions along the way. The tin alloy casting in silicone sounds very interesting! I have a friend who does lots of silicone moulding but had never heard of it being used in this way. Currently also working on a Cigarette race boat scratch build. Decided to mould. Thanks again Pete, all the best Cheers Mike

LikeLike